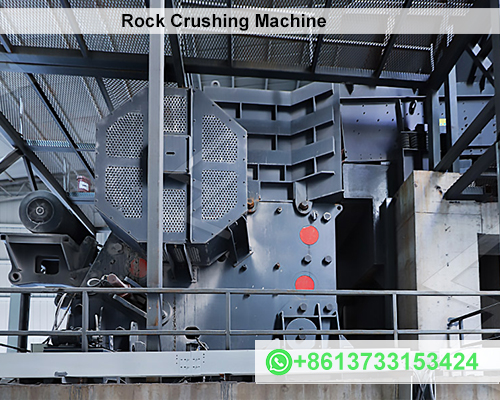

Cost of Rock Crushing Machine

When it comes to the mining, construction, and aggregate industries, rock crushing machines play a critical role. These machines are essential for breaking down large rocks into smaller, manageable sizes for various applications. However, understanding the cost associated with rock crushing machines is crucial for businesses looking to invest in this equipment. This article explores the factors influencing the cost, the types of machines available, and the overall economic implications.

Factors Influencing the Cost

- Type of Machine: There are various types of rock crushing machines, including jaw crusher, cone crusher, impact crusher, and mobile crusher. Each type comes with its own pricing structure based on its capabilities, size, and intended application.

- Capacity and Size: Larger machines with higher processing capacities typically come with a higher price tag. Businesses need to assess their production needs to choose a machine that balances cost with required output.

- Brand and Quality: Established brands often charge a premium for their machines due to reliability and after-sales support. However, lower-cost options might come with trade-offs in terms of durability and efficiency.

- Additional Features: Advanced features, such as automation, energy efficiency, and integrated screening, can increase the cost of a rock crushing machine. However, these features may enhance productivity and reduce operating costs in the long run.

- New vs. Used Equipment: Purchasing new machines generally costs more upfront but may offer better performance and warranties. Used machines can be significantly cheaper but may require more maintenance and repairs.

Average Cost Range

The cost of rock crushing machines can vary widely:

- Jaw Crusher: Typically range from $15,000 to $150,000, depending on size and features.

- Cone Crusher: Prices usually fall between $25,000 and $300,000, with high-performance models exceeding this range.

- Impact Crusher: These machines often cost between $30,000 and $200,000.

- Mobile Crusher: Due to their versatility and convenience, mobile crusher can range from $100,000 to over $1 million, depending on size and capabilities.

Economic Implications

Investing in a rock crushing machine is a significant financial decision. While the initial purchase price is important, businesses must also consider:

- Operating Costs: This includes fuel, maintenance, labor, and parts replacement. Efficient machines can lead to lower overall operating costs.

- Return on Investment (ROI): Evaluating how quickly the machine will pay for itself through increased productivity and lower material costs is essential for financial planning.

- Market Demand: Fluctuating demand for crushed rock in the construction and aggregate industries can impact profitability and the feasibility of the investment.

Conclusion

The cost of rock crushing machines is influenced by a myriad of factors, including the type of machine, capacity, brand, and additional features. Businesses must conduct thorough research and cost analysis to ensure they select the right equipment that meets their needs and budget. Ultimately, the right investment can lead to enhanced productivity and long-term savings, making it a worthwhile consideration for companies in the mining and construction sectors.