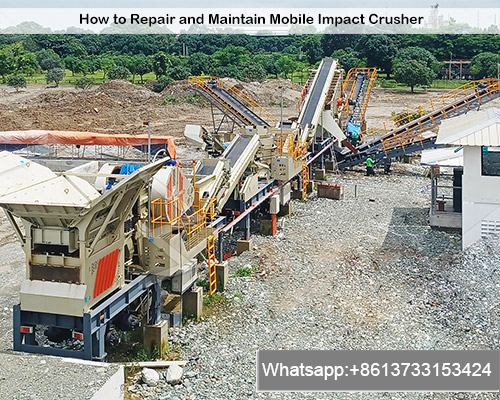

How to Repair and Maintain Mobile Impact Crusher?

Mobile impact crusher is essential pieces of equipment in the construction and demolition industry. They is used to break down large pieces of material into smaller ones, which can then be used for a variety of purposes, such as road construction, landscaping, and recycling. However, like any piece of machinery, mobile impact crusher need to be repaired and maintained on a regular basis in order to keep them running smoothly and efficiently.

Daily Maintenance

The following tasks should be performed on a daily basis:

- Inspect the crusher for any signs of damage or wear. This includes checking for cracks, loose bolts, and worn parts.

- Check the hydraulic fluid level and condition. Add fluid or replace the fluid as needed.

- Grease all of the zerk fittings.

- Check the belt tension and alignment. Adjust the belts as needed.

- Check the electrical system for any problems.

- Clean the crusher off of any debris.

Weekly Maintenance

In addition to the daily maintenance tasks, the following tasks should be performed on a weekly basis:

- Inspect the blow bars for wear. Replace the blow bars as needed.

- Check the liner plates for wear. Replace the liner plates as needed.

- Check the bearings for wear and noise. Replace the bearings as needed.

Monthly Maintenance

The following tasks should be performed on a monthly basis:

- Change the engine oil and filter.

- Change the hydraulic filter.

- Lubricate all of the bearings.

- Inspect the tires for wear and damage. Replace the tires as needed.

Preventative Maintenance

In addition to the daily, weekly, and monthly maintenance tasks, it is also important to perform preventative maintenance on a regular basis. This includes:

- Having the crusher inspected by a qualified technician on an annual basis.

- Following the manufacturer’s recommended maintenance schedule.

- Using the correct type of oil and hydraulic fluid.

- Keeping the crusher clean and free of debris.

Repairing Mobile Impact crusher

Mobile impact crusher can be repaired by a qualified technician. However, some minor repairs can be made by the operator. These include:

- Replacing worn or damaged parts.

- Adjusting the belt tension and alignment.

- Cleaning the electrical system.

Safety

When repairing or maintaining a mobile impact crusher, it is important to follow all safety precautions. This includes:

- Wearing the proper safety gear, such as safety glasses, gloves, and hearing protection.

- Locking out the crusher before performing any work.

- Using the proper tools and equipment.

- Following the manufacturer’s instructions.

By following these tips, you can help to keep your mobile impact crusher running smoothly and efficiently for years to come.