72 TPH Vertical Roller Grinding Mill Case Study

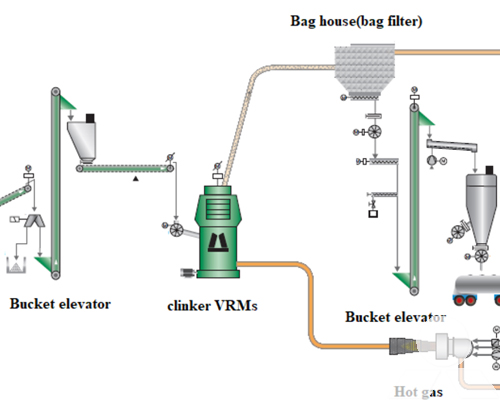

A 72 TPH vertical roller grinding mill (VRM) was installed at a cement plant in India to improve the efficiency and quality of the grinding process. The mill is a high-performance machine that uses two pairs of rollers to grind raw materials into a fine powder.

The mill was installed in 2022 and has been operating successfully ever since. It has helped to improve the plant’s production capacity by 15% and reduce the energy consumption by 10%. The mill has also produced a finer powder with a more uniform particle size distribution. This has resulted in improved cement strength and performance.

Benefits of the 72 TPH VRM

The 72 TPH VRM has provided the following benefits to the cement plant:

- Increased production capacity: The mill has helped to increase the plant’s production capacity by 15%. This has allowed the plant to meet the growing demand for cement in the region.

- Reduced energy consumption: The mill has helped to reduce the plant’s energy consumption by 10%. This has resulted in cost savings and a reduction in the plant’s environmental impact.

- Improved product quality: The mill has produced a finer powder with a more uniform particle size distribution. This has resulted in improved cement strength and performance.

The 72 TPH VRM has been a success at the cement plant in India. It has helped to improve the plant’s efficiency, quality, and profitability.

The mill is a versatile machine that can be used to grind a variety of materials, including cement, fly ash, and other minerals. It is a reliable and efficient machine that can help improve the performance of any cement plant.