Basic Structure Components Modeling PDF of Coal Mill Machines

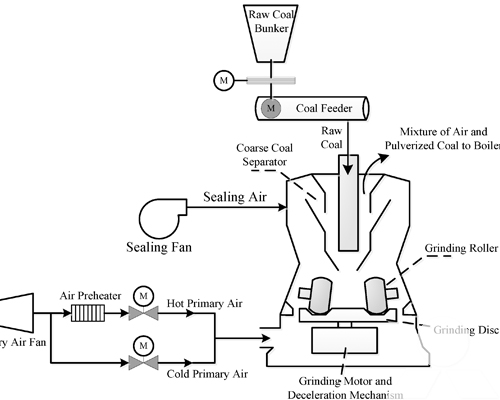

Coal mill are used to grind coal into a fine powder for use in a variety of applications, such as power generation, steelmaking, and cement production. Coal mills are complex machines with a variety of components. The basic structure components of a coal mill can be divided into two categories: the mechanical structure and the electrical structure.

Mechanical Structure

The mechanical structure of a coal mill is responsible for the grinding of the coal. The main components of the mechanical structure are the following:

- Rotor: The rotor is the rotating part of the coal mill. It is made of a strong material, such as steel or cast iron. The rotor is fitted with teeth or hammers that grind the coal.

- Stator: The stator is the stationary part of the coal mill. It is made of a strong material, such as steel or cast iron. The stator has teeth or hammers that mesh with the teeth or hammers on the rotor.

- Mill shell: The mill shell is the outer casing of the coal mill. It is made of a strong material, such as steel or cast iron. The mill shell protects the internal components of the coal mill.

- Grinding chamber: The grinding chamber is the space between the rotor and stator. The grinding chamber is where the coal is ground.

- Feeding device: The feeding device is used to feed the coal into the grinding chamber. The feeding device can be a hopper, a conveyor belt, or a screw conveyor.

- Discharge device: The discharge device is used to discharge the ground coal from the grinding chamber. The discharge device can be a conveyor belt, a screw conveyor, or a chute.

Electrical Structure

The electrical structure of a coal mill is responsible for the power supply to the mechanical structure. The main components of the electrical structure are the following:

- Motor: The motor provides the power to drive the rotor. The motor can be an electric motor or a steam turbine.

- Gearbox: The gearbox reduces the speed of the motor to a speed that is suitable for the rotor.

- Control system: The control system controls the speed of the rotor and the feed rate of the coal.

Modeling of Basic Structure Components

The basic structure components of a coal mill can be modeled using a variety of methods. One common method is to use three-dimensional solid modeling software. This software can be used to create a detailed model of the components, including their shape, dimensions, and material properties.

Another common method for modeling coal mill components is to use finite element analysis (FEA) software. FEA software can be used to simulate the behavior of the components under load. This can be used to analyze the strength and stiffness of the components, as well as their fatigue life.

The choice of modeling method depends on the specific needs of the application. If a detailed model of the components is required, then three-dimensional solid modeling software is a good option. If the behavior of the components under load needs to be analyzed, then FEA software is a good option.

Coal mills are complex machines with a variety of components. The basic structure components of a coal mill can be divided into two categories: the mechanical structure and the electrical structure. The mechanical structure is responsible for the grinding of the coal, while the electrical structure provides the power supply to the mechanical structure. The basic structure components of a coal mill can be modeled using a variety of methods, such as three-dimensional solid modeling software or finite element analysis (FEA) software.