Closed Circuit Impact Crusher Maximizing Efficiency and Performance

The impact crusher is a critical piece of equipment in various industries, particularly in mining, construction, and recycling. When used in a closed circuit configuration, it can significantly enhance performance by ensuring continuous material flow, improving product quality, and increasing operational efficiency. In this article, we’ll explore what a closed circuit impact crusher is, its advantages, and how it is used in different industries.

What Is a Closed Circuit Impact Crusher?

A closed circuit impact crusher refers to a crusher that operates with a closed-loop system, where the material is crushed and then screened for size. Once the material passes through the impact crusher, it is separated into two streams:one stream containing the finer material that is ready for use, and another containing the larger material that is sent back into the crusher for further processing.

This is achieved by incorporating a screening system that allows the material to be separated by size, with the larger particles being recirculated into the crusher. The closed circuit process allows for a more controlled, efficient, and uniform output of crushed material.

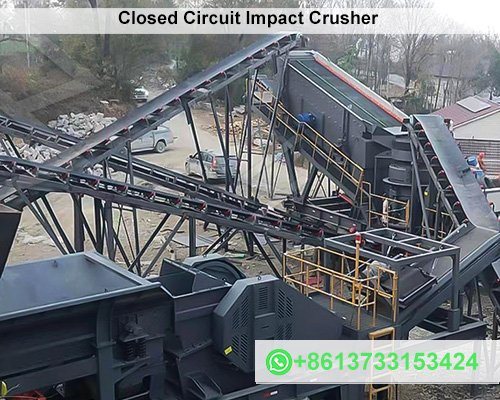

The closed circuit setup can be designed with a variety of screening and conveying equipment, including vibrating screens, classifiers, and conveyors. The material that passes through the crusher without further crushing is typically more consistent in size and quality, which is especially important in industries like construction and asphalt production.

Key Components of a Closed Circuit Impact Crusher

- Impact Crusher:The central component of the system, which uses impact force to crush materials like rocks, limestone, or concrete into smaller particles.

- Screening System:Typically a vibrating screen or a similar device that separates the material by size after it has been crushed. The screen ensures that only materials of a certain size exit the circuit.

- Return Conveyor:The material that does not meet the required size specifications is returned to the crusher via a conveyor system for further crushing.

- Product Conveyor:Once the material is crushed to the desired size, it is transferred to a separate conveyor for transport or processing.

How Does a Closed Circuit Impact Crusher Work?

The process starts with the material being fed into the impact crusher. Inside the crusher, the material is subjected to high-speed rotational forces created by hammers or blow bars. These forces fracture the material and reduce it to a smaller size.

The crushed material is then directed to a screening system, which separates the fines (smaller particles) from the larger ones. The fines are collected as the desired product, while the larger particles are sent back into the crusher for further processing.

This closed-loop process ensures that the material is continuously refined and recirculated until it meets the required specifications. The closed circuit design eliminates the need for additional crushing stages and optimizes the use of both the crusher and screening equipment.

Advantages of a Closed Circuit Impact Crusher

- Improved Product Quality:The closed circuit system ensures a consistent product size, which is essential for producing high-quality material. By recycling the larger particles, the crusher can continuously produce a uniform product.

- Higher Efficiency:Because the material is screened and recirculated within the system, the need for external processing is reduced. This minimizes material waste and enhances the overall efficiency of the operation.

- Reduced Operational Costs:The closed circuit design reduces the need for additional crusher, screens, and material handling equipment. This helps lower equipment costs, reduce downtime, and lower maintenance costs.

- Continuous Operation:A closed circuit system allows for continuous processing of materials, as the flow remains constant. This is particularly useful in industries that require high throughput, such as aggregate production and recycling.

- Better Control Over Output:The ability to control the material size via screening ensures that the output meets precise specifications. This is particularly valuable when producing materials for specific applications, such as asphalt production or concrete mix.

- Environmental Benefits:By recirculating the material that does not meet specifications, closed circuit systems help reduce waste and ensure that more material is utilized. This contributes to sustainable and efficient operations.

Applications of Closed Circuit Impact Crusher

1. Aggregate Production

In aggregate production, a closed circuit impact crusher is commonly used to produce uniform-sized gravel, sand, and crushed stone for construction purposes. The closed circuit ensures that only material of the desired size is delivered, optimizing the production of concrete, asphalt, and other construction materials.

2. Recycling

Closed circuit impact crusher is particularly effective in recycling operations, especially for crushing concrete and asphalt. The closed-loop system ensures that the output material is the right size for reuse in new construction projects, reducing the need for virgin materials.

3. Mining

In the mining industry, closed circuit impact crusher is used for processing ores, especially when fine product sizes are required. These crusher provide efficient and controlled crushing, minimizing over-crushing and maximizing recovery.

4. Road Construction

For road construction projects, where consistent and uniform-sized aggregates are critical, closed circuit impact crusher offer significant advantages. They ensure that the right-sized material is consistently produced, improving the quality of the final product.

5. Industrial and Recycling Waste

Closed circuit impact crusher is also used in various industrial and recycling operations to process waste materials such as glass, ceramics, and plastics. The closed-loop design allows operators to handle a wide variety of materials efficiently.

Leading Manufacturers of Closed Circuit Impact Crusher

Several key manufacturers provide high-quality closed circuit impact crusher that are used in various industries. Some of the leading brands include:

- Metso Outotec:Known for their extensive range of crusher, including closed circuit impact crusher, Metso offers highly reliable and efficient models that are used in multiple industries worldwide.

- Sandvik:Sandvik’s range of impact crusher includes models designed specifically for closed circuit operations, offering superior crushing efficiency and ease of maintenance.

- Terex:Terex provides advanced impact crusher suitable for a wide range of applications, including closed circuit systems, providing flexibility and high throughput.

- McCloskey:McCloskey’s impact crusher is known for their robust construction and excellent performance in closed circuit systems, providing operators with high efficiency and low operating costs.

- Powerscreen:Powerscreen manufactures closed circuit impact crusher designed for high performance, durability, and minimal downtime in various material processing applications.

Conclusion

A closed circuit impact crusher is a highly effective piece of equipment that maximizes performance by recirculating oversized material back into the crusher for further reduction. Its continuous operation, enhanced efficiency, and ability to deliver consistent product size make it an invaluable tool for industries like construction, mining, and recycling. By investing in a closed circuit impact crusher, companies can optimize their material processing, reduce operational costs, and improve product quality, ensuring that they remain competitive in an ever-evolving market.