Ball mill for manufacturing wall putty for sale in india

Ball mills are versatile grinding machines commonly used in various industries for the preparation and refinement of materials. One of the key applications of ball mills is in the manufacturing of wall putty. Wall putty is a vital component in the construction industry, serving as a primary material for smoothening and leveling walls before painting. This article explores the role of ball mills in producing high-quality wall putty.

The Composition of Wall Putty: Wall putty is a paste-like substance that primarily consists of white cement, finely powdered fillers, polymer binders, and water. The main purpose of wall putty is to create a smooth, even surface on walls by filling imperfections and minor cracks, providing an ideal base for paint application. To achieve the desired consistency and quality, the ingredients must be thoroughly mixed and finely ground, which is where ball mills come into play.

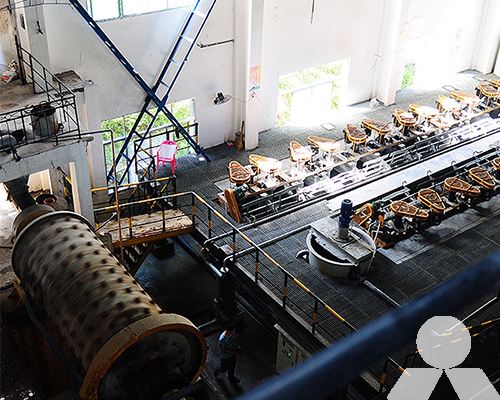

Ball Mill Operation and Process: A ball mill is a cylindrical device used to grind or mix materials like ores, chemicals, ceramic raw materials, and paints. In the case of manufacturing wall putty, the ingredients are loaded into the drum of the ball mill. The drum is then rotated, causing the grinding media (usually metallic balls) within to cascade and grind the mixture into a fine powder.

During the grinding process, the rotation of the drum and the movement of the grinding media create a high impact and shear force, effectively breaking down the particles into smaller sizes. This process ensures uniform distribution of each component within the mixture, resulting in a homogeneous blend of white cement, fillers, and polymer binders. The addition of water during the grinding process helps achieve the desired paste-like consistency of the wall putty.

Advantages of Using Ball Mills for Wall Putty Manufacturing:

- Uniform Particle Size: Ball mills ensure consistent and fine grinding, leading to a uniform particle size distribution. This uniformity contributes to the smooth texture of the wall putty.

- Homogeneous Mixture: The intense grinding action within the ball mill results in a thorough blending of the different components, preventing the segregation of ingredients and ensuring the wall putty’s overall quality.

- Precise Control: Ball mills allow for precise control over the grinding process, enabling manufacturers to achieve the exact consistency and properties required for high-quality wall putty.

- Efficiency: Ball mills are efficient grinding machines that consume less energy compared to other methods, making them an environmentally friendly choice for wall putty manufacturing.

In the construction industry, the application of ball mills for manufacturing wall putty plays a pivotal role in producing a smooth and even surface for painting. By effectively grinding and blending the ingredients, ball mills ensure the uniform distribution of white cement, fillers, polymer binders, and water, resulting in a high-quality wall putty product. The use of ball mills not only enhances the efficiency of the manufacturing process but also contributes to the overall aesthetic appeal and longevity of painted walls.