Difference between cone crusher and jaw crusher

Cone crusher and jaw crusher is two common types of machines used to break down large rocks and minerals into smaller pieces. They is both used in a variety of industries, including mining, quarrying, and construction. However, there is some key differences between the two types of crusher that make them more suitable for different applications.

Crushing Mechanism

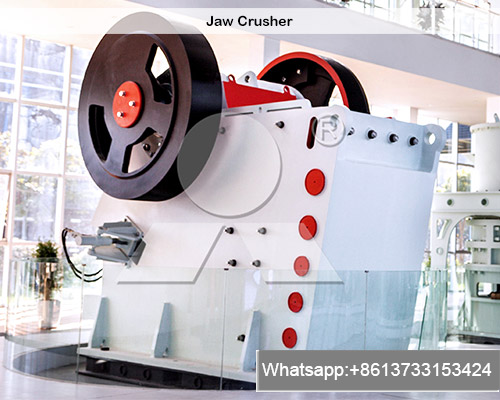

- Jaw crusher:A jaw crusher works by using two stationary jaws that open and close, crushing the material that is fed between them. The size of the crushed material is determined by the gap between the jaws.

- Cone crusher:A cone crusher works by using a rotating cone-shaped mantle that crushes the material against a concave bowl liner. The size of the crushed material is determined by the gap between the mantle and the bowl liner.

Application

- Jaw crusher: Jaw crusher is typically used for primary crushing, which is the first stage of the crushing process. They is well-suited for crushing large, hard rocks and minerals.

- Cone crusher: Cone crusher is typically used for secondary and tertiary crushing, which is the later stages of the crushing process. They is well-suited for crushing smaller, more friable materials.

Advantages and Disadvantages

Jaw crusher

Advantages:

- Simple and robust design

- Easy to maintain

- Low cost

- Can handle a wide range of materials

Disadvantages:

- Produces a less cubical product

- Has a lower crushing ratio

- Can be dusty

Cone crusher

Advantages:

- Produces a more cubical product

- Has a higher crushing ratio

- Less dusty

Disadvantages:

- More complex and expensive than jaw crusher

- More difficult to maintain

- Cannot handle as wide a range of materials

Choosing the Right Crusher

The type of crusher that is right for a particular application will depend on a number of factors, including the size and hardness of the material, the desired product size, the production capacity required, and the budget.

In general, jaw crusher is a good choice for primary crushing applications where a large, robust machine is needed. Cone crusher is a good choice for secondary and tertiary crushing applications where a high-quality, cubical product is required.