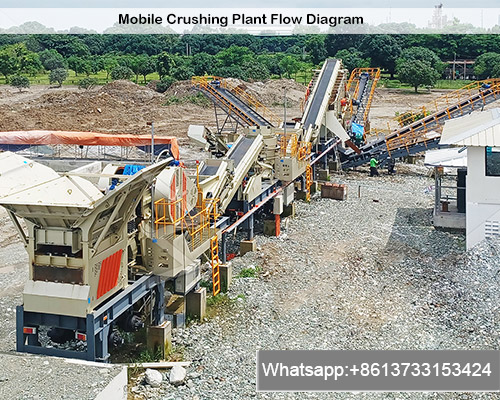

Mobile crushing plant flow diagram

Mobile crushing plant are marvels of engineering, offering a compact and efficient solution for rock and material size reduction on the go. But how exactly do these portable giants achieve their task? This is where the concept of a mobile crushing plant flow diagram comes in.

What is a Mobile Crushing Plant Flow Diagram?

A mobile crushing plant flow diagram is a visual representation of the material’s journey through the various stages of processing within the plant. It outlines the equipment involved and the sequence of operations that transform large rocks into desired sized products.

Typical Stages in a Mobile Crushing Plant Flow Diagram:

- Feeding: The process begins with the raw material being loaded into a feed hopper. A vibrating feeder then precisely meters the material onto a conveyor belt.

- Primary Crushing: The material travels along the conveyor to the primary crusher, typically a jaw crusher. This crusher breaks down the large rocks into smaller, more manageable pieces.

- Optional: Primary Screening: Some mobile plant incorporate a primary screen after the crusher. This screen separates out any material already small enough for further processing, bypassing it and increasing overall efficiency.

- Secondary Crushing: The partially crushed material is then transported to a secondary crusher, often a cone crusher. This crusher further reduces the size of the material to meet the desired specifications.

- Stockpiling or Further Processing: The final product exits the crusher and can be stockpiled for later use or directed to additional processing equipment, such as a vibrating screen for size classification.

Benefits of Understanding Flow Diagrams:

Understanding mobile crushing plant flow diagrams offers several benefits:

- Optimizing Production: By visualizing the process flow, operators can identify bottlenecks and adjust feeding rates or crusher settings to maximize production.

- Improved Equipment Performance: The flow diagram highlights the interaction between different equipment pieces. This allows for proper maintenance scheduling and ensures smooth operation of the entire plant.

- Enhanced Safety: Flow diagrams often include safety protocols for each stage of the process. This visual reminder helps to ensure a safe working environment for plant personnel.

Mobile crushing plant flow diagrams are essential tools for understanding and optimizing the rock crushing process. By providing a clear picture of material movement and equipment interaction, they empower operators to achieve efficient and safe production.