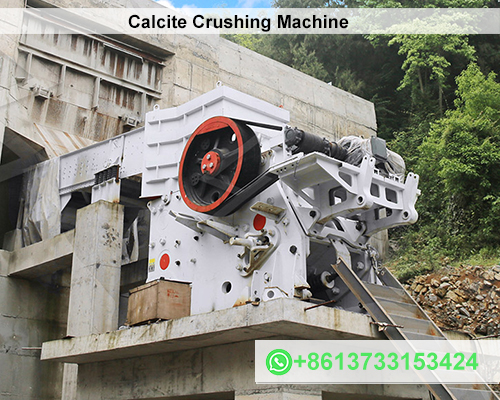

Calcite Crushing Machine Manufacturer and Price

Calcite, a naturally occurring mineral composed of calcium carbonate (CaCO₃), is a vital material used across various industries, including construction, agriculture, chemical, and pharmaceuticals. Its widespread use drives the demand for efficient calcite crushing machinery. The proper choice of equipment ensures the right particle size and reduces processing costs, making calcite crusher essential for industries that require finely milled calcite.

This article will explore the key manufacturers of calcite crushing machines, the types of equipment available, and the price ranges for these machines.

Leading Calcite Crushing Machine Manufacturers

Several manufacturers specialize in the design and production of calcite crusher. Here are some of the leading names in the industry:

1. Shanghai Zenith Minerals Co., Ltd.

Zenith is a global leader in the crushing and grinding industry. Their calcite crusher, such as the jaw crusher, impact crusher, and cone crusher, are highly efficient and reliable. Zenith’s machines are known for their durability, precision, and energy efficiency.

2. Liming Heavy Industry

Liming Heavy Industry manufactures high-quality crushing equipment tailored to process calcite and other minerals. Their jaw crusher and impact crusher is designed to handle large amounts of calcite and offer superior performance in terms of crushing ratio and capacity.

3. SBM (Shibang Industry & Technology Group Co., Ltd.)

SBM is renowned for its innovative crusher that deliver high crushing efficiency. They offer portable crusher, mobile crusher, and stationary crushing equipment, which can process calcite into different particle sizes for various industrial applications.

4. Metso Outotec

A well-known name in the mining and aggregate industries, Metso Outotec provides advanced solutions for calcite crushing. Their HP and GP series cone crusher offer high-performance crushing with minimal operational costs.

Types of Calcite Crushing Machines

When selecting a calcite crusher, the choice depends on the desired output size, the type of application, and the material’s hardness. Below are common types of crusher used for calcite:

1. Jaw Crusher

Jaw crusher is commonly used for primary crushing. They can handle large chunks of calcite and reduce them into smaller, manageable sizes. Known for their durability and efficiency, they are a preferred option in many industries.

2. Cone Crusher

Cone crusher is often used for secondary or tertiary crushing. They offer high crushing efficiency and are ideal for producing fine or medium-sized particles. For industries needing calcite powders or smaller aggregates, cone crusher is the best option.

3. Impact Crusher

Impact crusher is suitable for processing softer calcite materials. They deliver consistent particle size and shape, making them popular in industries requiring precision in their products. These machines are known for their energy-efficient design and cost-effectiveness.

4. Mobile Crusher

Mobile crushing machines offer flexibility and convenience, especially for industries that operate at multiple sites or need to transport the equipment. Mobile crusher from top manufacturers come with advanced features such as automated controls and high mobility.

Price Range for Calcite Crushing Machines

The cost of calcite crushing machinery varies based on the type of machine, manufacturer, and specific features. Below is an estimate of the price range for different types of crusher:

- Jaw Crusher: Prices for calcite jaw crusher range from $5,000 to $50,000, depending on size and capacity. Smaller models suited for lab work or small-scale operations are on the lower end, while heavy-duty, industrial-grade models can reach higher price points.

- Cone Crusher: Cone crusher typically range from $10,000 to $100,000. The price depends on the crusher’s size, crushing capacity, and automation features. High-end models equipped with advanced control systems are priced at the upper range.

- Impact Crusher: Impact crusher cost between $8,000 and $80,000, with prices varying depending on capacity, energy efficiency, and output size customization. Machines designed for finer crushing and higher precision tend to be more expensive.

- Mobile Crusher: Mobile crusher is among the more expensive options, with prices ranging from $50,000 to $300,000. The mobility, versatility, and automation features of mobile crusher make them suitable for large-scale operations, justifying the higher price.

Factors Affecting Prices

Several factors can influence the price of calcite crushing machines, including:

- Capacity: Machines with higher processing capacities tend to cost more.

- Automation: Crusher with advanced automation systems and remote monitoring features are generally more expensive.

- Material Quality: The durability and longevity of the machine components can affect the price, as more robust materials lead to longer operational life.

- Brand Reputation: Established manufacturers with a global reputation may charge a premium for their machines due to their proven performance, customer service, and reliability.

Investing in a reliable calcite crushing machine is crucial for businesses involved in calcite processing. The choice of equipment depends on the required output size, budget, and operational needs. Leading manufacturers like Zenith, Liming Heavy Industry, SBM, and Metso Outotec offer a range of crusher suited for different applications, ensuring optimal performance and efficiency. Prices vary depending on the type and capacity of the machine, making it essential for buyers to carefully assess their specific requirements before making a purchase.

Whether you’re a small-scale operator or a large industrial player, selecting the right crushing equipment will help improve efficiency, reduce costs, and boost overall productivity in calcite processing.