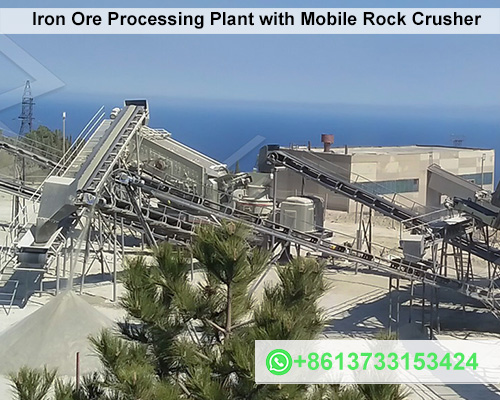

Iron Ore Processing Plant with Mobile Rock Crusher

Looking to optimize your iron ore operations with cutting-edge technology? An iron ore processing plant with mobile rock crusher offers unmatched flexibility, cost savings, and productivity for modern mining projects. This innovative setup combines stationary processing power with the agility of mobile crushing, making it ideal for remote sites and dynamic workflows. Discover how this solution can transform your mining operations.

What Is an Iron Ore Processing Plant with Mobile Rock Crusher?

An iron ore processing plant integrates crushing, screening, and beneficiation equipment to convert raw ore into marketable products like pellets or concentrates. Adding a mobile rock crusher enhances this system by introducing portability. Key components include:

- Mobile crusher: Track or wheel-mounted units that crush ore directly at extraction sites.

- Conveyor systems: Transport crushed material to stationary processing units.

- Screening and sorting: Separate ore by size and grade.

- Beneficiation equipment: Magnetic separators or flotation cells to refine ore quality.

This hybrid model reduces reliance on fixed infrastructure, enabling faster setup and scalability.

Why Combine a Mobile Crusher with an Iron Ore Processing Plant?

1. Operational Flexibility

Mobile crusher eliminate the need to transport raw ore long distances to stationary plants. Crushing at the source slashes hauling costs and minimizes downtime, especially in remote or temporary mining sites.

2. Cost Efficiency

- Lower fuel and labor costs: On-site crushing reduces trucking requirements.

- Reduced capital investment: Mobile units avoid the high costs of permanent plant installations.

- Scalability: Easily adjust capacity by adding or relocating crusher as ore reserves shift.

3. Enhanced Productivity

Modern mobile crusher deliver high throughput (up to 500+ tons per hour) and can handle tough iron ore with abrasion-resistant components. Real-time monitoring systems optimize performance and prevent bottlenecks.

4. Sustainability Benefits

- Lower emissions: Electric or hybrid mobile crusher reduce carbon footprints.

- Resource efficiency: Precise crushing minimizes waste and maximizes ore recovery.

Key Applications in Iron Ore Mining

- Primary Crushing: Break down large ore chunks (up to 1.5m) into manageable sizes.

- In-Pit Crushing and Conveying (IPCC): Integrate mobile crusher with conveyor belts to streamline material flow.

- Tailings Management: Reprocess waste material to extract residual iron.

- Exploration Sites: Rapidly deploy crusher for small-scale or trial operations.

How to Choose a Mobile Rock Crusher for Iron Ore

When selecting equipment for your iron ore processing plant, prioritize these factors:

- Ore Characteristics: Match crusher type (e.g., jaw, cone, or impact) to ore hardness, moisture, and silica content.

- Mobility: Track-mounted crusher excel on rough terrain; wheeled models suit established roads.

- Capacity: Ensure throughput aligns with your plant’s daily production goals.

- Durability: Opt for crusher with reinforced steel frames and wear-resistant liners.

- Brand Support: Choose reputable manufacturers like Liming Heavy Industry, SBM for reliable service and parts.

FAQs About Iron Ore Processing Plants with Mobile Crusher

Q: What’s the average cost of a mobile rock crusher for iron ore?

A: Prices range from 300,000 to 300,000 to 300,000 to 2.5 million, depending on size, technology, and brand.

Q: Can mobile crusher handle abrasive iron ores like hematite or magnetite?

A: Yes, but ensure the crusher has hardened blow bars, liners, and regular maintenance schedules.

Q: How does a mobile setup improve ore recovery rates?

A: By crushing ore to optimal sizes on-site, you enhance downstream beneficiation efficiency.

Q: Are hybrid or electric mobile crusher available?

A: Many brands now offer eco-friendly electric models, ideal for mines targeting net-zero goals.

Upgrade Your Iron Ore Operations Today!

Integrating a mobile rock crusher into your iron ore processing plant is a strategic move to boost profitability, adaptability, and sustainability. Whether you’re expanding an existing mine or launching a new project, this solution ensures you stay competitive in a demanding industry.