Working Principle Animation of Cone Crusher

Cone crushers are essential equipment in the field of mining and aggregates processing. They play a crucial role in breaking down large rocks into smaller, more manageable pieces.

Working Principle Animation

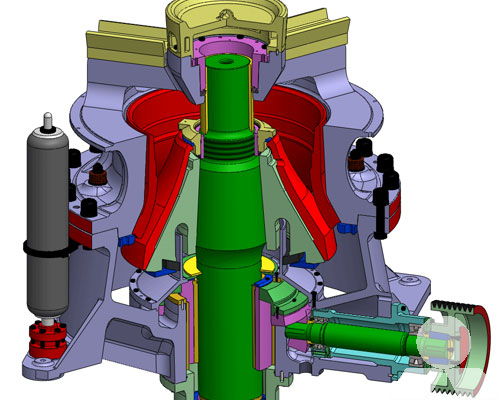

Scene 1: Cone Crusher Setup

The animation begins with a visual of a cone crusher set up on a platform within a mining site. A large cone-shaped crushing surface, the mantle, is depicted at the center of the scene, and a smaller, conical crushing head, the concave, is positioned above it. The platform also shows a conveyor belt for feeding rocks into the crusher.

Scene 2: Feed Entry and Crushing

As rocks are fed into the cone crusher through the conveyor belt, they fall into the space between the mantle and concave. This is where the crushing action takes place. The mantle, which is in constant rotation, moves eccentrically to create a squeezing motion on the incoming rocks.

Scene 3: Crushing Process

The animation focuses on the crushing process. The eccentric movement of the mantle causes the gap between the mantle and concave to narrow and widen rhythmically. As the rocks enter the narrowing gap, they are compressed and crushed into smaller fragments due to the intense pressure exerted by the mantle. The animation showcases this compression through visual representations of rocks being shattered into smaller pieces.

Scene 4: Discharge of Crushed Material

After the rocks are sufficiently crushed, the animation shifts to the discharge process. The crushed material, now in smaller fragments, exits the crusher through the bottom opening between the mantle and concave. This opening is adjustable, allowing operators to control the size of the crushed material.

Scene 5: Recap and Key Features

The animation concludes by summarizing the key features and benefits of cone crushers:

- Efficient Crushing: The cone crusher’s squeezing and compressing action leads to efficient and effective reduction of large rocks into smaller particles.

- Adjustable Output: The adjustable opening between the mantle and concave enables operators to produce different sizes of crushed material according to their specific requirements.

- Uniform Particle Size: The crushing process results in a more uniform particle size distribution, which is vital for downstream processes like screening and further refinement.

- Robust Construction: Cone crushers are designed with robust materials to withstand the demanding conditions of mining and aggregates processing.

- Versatility: Cone crushers can be used for various types of materials, from hard and abrasive rocks to softer, more friable materials.

The animated depiction of a cone crusher’s working principle provides a comprehensive understanding of how this essential piece of equipment functions. By effectively breaking down larger rocks into smaller fragments, cone crushers contribute significantly to the mining and aggregates industries, facilitating further processing and utilization of materials.