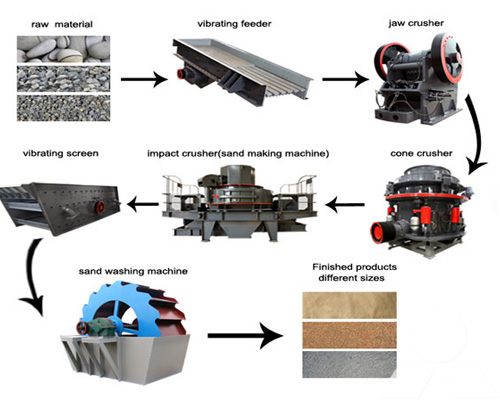

Sand Production Line Process

A sand production line is a type of equipment used to produce high-quality sand and stone, widely used in construction, roads, railways, water conservancy, and other fields. This article will introduce the process of a sand production line, including raw material processing, crushing, screening, washing, and quality control of finished sand.

I. Raw Material Processing

The raw materials of the sand production line mainly include limestone, granite, basalt, and river pebbles. In the raw material processing stage, the raw materials need to be screened and washed preliminarily to remove impurities and soil. The purpose of this step is to ensure the subsequent crushing and screening can proceed smoothly and improve the quality of the finished sand.

II. Crushing

Crushing is the core process of the sand production line, mainly involving coarse and fine crushing. Coarse crushing refers to the preliminary crushing of raw materials, usually using jaw crushers or impact crushers. Fine crushing refers to further crushing of the coarse-crushed raw materials, usually using cone crushers or impact crushers. The particle size of the crushed raw materials should meet the production requirements, and attention should be paid to controlling the outlet size of the crusher to ensure that the subsequent screening can proceed smoothly.

III. Screening

Screening is the process of grading the crushed raw materials, usually using a vibrating screen or a rotating screen. The purpose of screening is to separate raw materials of different particle sizes for subsequent washing and preparation of finished sand. In the screening process, attention should be paid to selecting and cleaning the sieve to ensure screening efficiency and production efficiency.

IV. Washing

Washing is the process of cleaning the screened raw materials, usually using a spiral sand washing machine or a wheel sand washing machine. The purpose of washing is to remove soil, impurities, and dust from the raw materials to ensure the quality of the finished sand. In the washing process, attention should be paid to controlling the water flow and water quality to avoid environmental pollution.

V. Quality Control of Finished Sand

Quality control of finished sand is the last step of the sand production line, mainly involving quality testing and screening of finished sand. Quality testing includes particle size analysis, moisture content detection, and strength testing to ensure the quality of the finished sand meets the production requirements. Screening is the classification of finished sand according to different uses for sales and use.

The process of a sand production line includes raw material processing, crushing, screening, washing, and quality control of finished sand. During the production process, attention should be paid to controlling the parameters and quality of each step to ensure the quality of the finished sand and production efficiency.