Copper Extraction Process Flow: Complete Guide With Equipment Diagram

As a leading manufacturer in mining machinery, Liming Heavy Industry specializes in providing robust solutions for the copper mining industry. Understanding the copper extraction process flow is crucial for optimizing production efficiency and reducing operational costs. This guide explores the entire copper extraction from ore process, with a focus on crushing technology and how our equipment enhances each stage.

Copper Ore Types and Characteristics

Copper ores are primarily categorized into oxide ores and sulfide ores. Oxide ores, such as cuprite and malachite, are typically processed through hydrometallurgical methods like heap leaching. Sulfide ores, including chalcopyrite and bornite, often require froth flotation or bioleaching techniques. Low-grade copper ores (with copper content between 0.2% and 1.5%) have become economically viable through advanced processing methods, making efficient crushing a critical first step.

Copper Extraction Process Flow

The copper extraction process flow generally involves several key stages: crushing, grinding, concentration, smelting, and refining. The specific approach depends on the ore type. For oxide ores, a common method is heap leaching followed by solvent extraction and electrowinning (SX-EW). This process involves spraying sulfuric acid (with a concentration of 5-20 g/L) over crushed ore heaps to dissolve copper, with the resulting solution undergoing solvent extraction to concentrate the copper, which is then recovered via electrowinning to produce high-purity cathode copper (≥99.95%). Sulfide ores are often concentrated by crushing, grinding, and froth flotation to produce a copper concentrate, which is then smelted.

Crushing and Processing Flow in Copper Extraction

Crushing is the primary and essential stage in the copper extraction process flow. The goal is to reduce the ore to a specific size (typically 10-30 mm) to optimize the surface area for subsequent leaching or grinding. The process typically involves:

- Primary Crushing: Large run-of-mine ore is reduced to about 150-200 mm using a robust jaw crusher.

- Secondary Crushing: The output from the primary crusher is further reduced by a cone crusher to a size suitable for grinding or heap leaching, often targeting 10-30 mm.

- Tertiary Crushing (if needed): For finer requirements, an impact crusher or fine cone crusher may be used.

If the ore has a high clay content, binders like cement or lime may be added for pelletization to improve heap permeability. The crushed ore is then stacked on an impermeable pad (lined with HDPE geomembranes) for heap leaching or conveyed to grinding mills for further processing.

Application Scope of Liming Heavy Industry Crushers in Copper Mining

Our crushing equipment is engineered to handle the abrasive nature of copper ores efficiently. The applications include:

- Primary Crushing: Our jaw crushers are ideal for the initial size reduction of copper ore directly from the mine.

- Secondary and Tertiary Crushing: Cone crushers are used for further size reduction, producing a uniform product for heap leaching or grinding circuits.

- Mobile and Modular Crushing Plants: Our SMP module crushing stations offer flexibility for remote mining sites, allowing for quick setup and relocation.

Our machines are suitable for processing various copper-bearing rocks, including porphyry copper, chalcocite, and chalcopyrite, as well as associated minerals.

Crusher Types and Capacities

Liming Heavy Industry offers a comprehensive range of crushers designed for high capacity and reliability in copper mining operations. Key products include:

| Crusher Type | Model Examples | Capacity Range (t/h) | Application in Copper Process |

|---|---|---|---|

| Jaw Crusher | PE1200×1500, PE900×1200 | 200-800 | Primary crushing of large copper ore |

| Cone Crusher | HST315, HPT300 | 150-550 | Secondary and tertiary crushing |

| Impact Crusher | PFW1315III | 180-350 | For softer ores or producing chip-shaped aggregates |

| SMP Module Crushing Line | Customized Configurations | 500-2000+ | Complete modular solution for large-scale copper mines |

These crushers are designed to handle feed sizes up to 1500 mm and produce final products adjustable within a wide range, meeting the specific requirements of the copper extraction process flow.

Technology and Innovations in Our Crushing Equipment

At Liming Heavy Industry, we integrate advanced technologies to maximize efficiency and uptime in copper ore crushing:

- Hydraulic Control Systems: Our cone crushers feature hydraulic adjustment and clearing systems, allowing for quick and easy setting changes and reducing downtime in case of uncrushable material.

- Wear-Resistant Materials: Critical components are made from high-manganese steel and other alloys to withstand the abrasiveness of copper ore, extending service life.

- Automation and Smart Control: Crushers can be equipped with automatic control systems that optimize the crushing process in real-time, ensuring consistent product size and maximizing throughput.

- Modular Design (SMP): Our SMP modular crushing plants enable faster delivery and installation (30%-40% faster than traditional lines) without the need for extensive concrete foundations, which is ideal for new or expanding copper mining projects.

Common Challenges and Solutions in Copper Ore Crushing

Copper mining operations often face specific challenges during the crushing stage. Here are common issues and how our equipment provides solutions:

- Challenge: High Abrasiveness and Hardness. Some copper ores are very abrasive, leading to rapid wear of crusher components.

Solution: Our crushers use specially designed wear parts made from ultra-hard alloys, significantly increasing their service life and reducing maintenance frequency. - Challenge: Moisture and Clay Content. Sticky ores can cause clogging in crushers and screens.

Solution: Our equipment selection and process design consider material characteristics. For example, we can recommend specific crusher cavity designs and feeding arrangements to minimize clogging. - Challenge: Achieving Optimal Particle Size. The efficiency of heap leaching is highly dependent on a consistent and appropriate particle size (e.g., 10-30 mm).

Solution: Our cone crushers offer precise control over the closed-side setting (CSS), allowing operators to fine-tune the product size for optimal leaching kinetics.

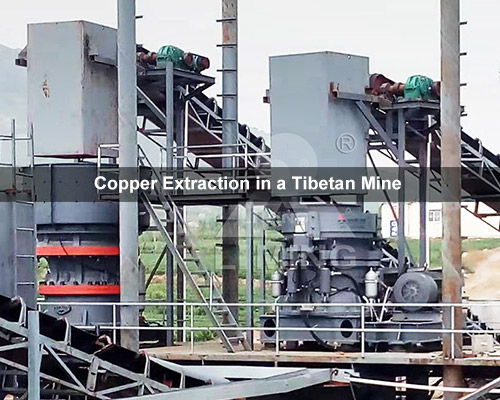

Case Study: Efficient Copper Extraction in a Tibetan Mine

A copper mine in Tibet processing oxide ore with an average grade of 0.8% successfully implemented a complete crushing and heap leaching circuit. The process utilized a two-stage crushing system with a Liming PE1200×1500 Jaw Crusher for primary crushing and an HST315 Cone Crusher for secondary crushing. The ore was reduced to a target size of 25 mm, which proved ideal for heap permeability. The mine adopted the heap leaching-SX-EW process, achieving a copper recovery rate of 85% and producing cathode copper with a purity of 99.97%. The robust performance of the crushing circuit ensured a consistent feed for leaching, contributing directly to the project’s high efficiency and economic success.

Why Choose Liming Heavy Industry for Your Copper Extraction Project?

Selecting the right crushing partner is vital for the success of your copper extraction process. Here’s why Liming Heavy Industry stands out:

- Proven Expertise: With decades of experience, we understand the specific needs of the copper mining industry.

- Comprehensive Product Range: We offer everything from individual crushers to complete, modular SMP crushing plants, providing a one-stop solution.

- Focus on Reliability and Efficiency: Our machines are built for high availability and low operating costs, directly impacting your bottom line.

- Global Support and Service: We provide extensive after-sales support, including technical consulting, spare parts supply, and maintenance services, ensuring your operations run smoothly.

Conclusion

The copper extraction from ore process is a complex but well-established sequence, where efficient crushing sets the foundation for overall success. From primary jaw crushers to modular SMP plants, Liming Heavy Industry provides reliable, high-performance equipment tailored to the demands of modern copper mining. By optimizing the crushing stage, miners can significantly improve the efficiency of downstream processes like heap leaching or flotation, leading to higher recovery rates and reduced operational costs. For your next project, partner with Liming Heavy Industry to leverage our technology and expertise in achieving an optimized copper extraction process flow.