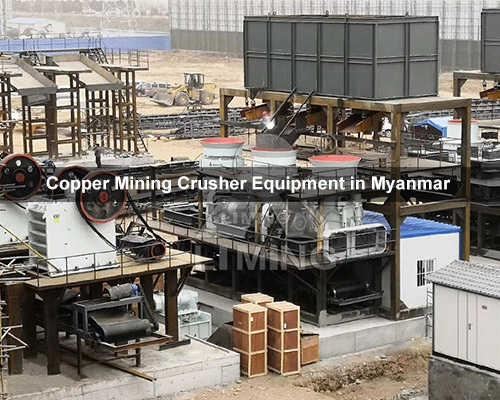

Copper Mining Crusher Equipment in Myanmar

Myanmar, located in Southeast Asia, has long been a country rich in natural resources. Among the most valuable minerals extracted from the region is copper, a critical component for numerous industrial applications, from electrical wiring to renewable energy technologies. The demand for copper has steadily risen, fueling growth in the mining sector. To meet these demands, modern mining techniques and efficient equipment are essential, with crusher playing a central role in the extraction and processing of copper ores.

Overview of Copper Mining in Myanmar

Myanmar boasts significant copper reserves, with major mining projects located primarily in the north and central parts of the country. The Letpadaung and Monywa mines are two of the largest copper mining operations in Myanmar, both contributing substantially to the country’s copper output. Mining operations are typically open-pit, and the extraction process involves multiple stages, including drilling, blasting, loading, hauling, and finally, processing.

The Role of Crusher in Copper Mining

Crushing is one of the first and most critical steps in the copper ore processing chain. The role of crusher in copper mining cannot be overstated, as they reduce large chunks of ore into manageable sizes for further processing. Crusher help in breaking down the ore into smaller, more uniform pieces, facilitating the extraction of copper from the rock.

There are several types of crusher used in the mining industry, each suited to different stages of ore processing:

- Jaw Crusher

Jaw crusher is commonly used in primary crushing. These crusher is designed to handle large, hard materials, making them ideal for reducing the size of copper ores extracted directly from the mine. They operate by compressing the material between two heavy jaws, with one fixed and the other moving. - Cone Crusher

Cone crusher is typically used for secondary and tertiary crushing stages. They are efficient for further reducing the size of copper ore and improving the consistency of particle size. Their unique conical design allows for better crushing efficiency, and they can handle harder materials without sacrificing throughput. - Impact Crusher

Impact crusher is used for processing softer materials or further reducing the size of copper ore after it has undergone primary and secondary crushing. They work by using high-speed impact forces to break down ore particles, which is especially useful for crushing irregularly shaped materials. - Roll Crusher

Roll crusher is often employed in stages of processing where finer control over particle size is required. They are effective at crushing relatively soft to medium-hard materials and are often used in tandem with other crusher to achieve the desired level of reduction. - Gyratory Crusher

Gyratory crusher is mainly used for primary crushing in large-scale operations. These machines feature a conical design and use a rotating spindle to break down material. They are known for their high throughput capacity, making them ideal for handling large quantities of ore.

Key Considerations for Crusher Selection in Copper Mining

The selection of the right crusher depends on several factors, including the hardness of the ore, the desired particle size, throughput capacity, and the available infrastructure at the mine site. In Myanmar, where copper mining operations are often located in remote areas, it is crucial to choose equipment that can withstand the challenges posed by harsh working conditions.

Factors influencing crusher selection:

- Ore Characteristics:Hardness, size distribution, and moisture content of the copper ore influence the choice of crusher. For instance, ores with higher hardness may require more robust crushing equipment.

- Crushing Capacity:The efficiency and capacity of crusher directly affect the overall productivity of the mine. Higher capacity crusher can reduce operational costs by processing more ore per hour.

- Energy Efficiency:Energy consumption is a significant factor in determining the cost-effectiveness of crusher. Modern crusher is designed to be energy efficient, helping to lower operational expenses in large-scale mining operations.

- Maintenance Requirements:In remote locations such as Myanmar’s mining regions, minimizing downtime is crucial. Selecting crusher that are durable, easy to maintain, and supported by a reliable service network is essential for continuous operation.

The Future of Copper Mining and Crusher Equipment in Myanmar

Myanmar’s copper mining industry continues to evolve, with increasing demand for higher-quality ores and more efficient processing methods. As the mining industry grows, so too does the need for more advanced and cost-effective crusher equipment. In recent years, there has been a trend towards automation and the integration of smart technologies in mining equipment. These innovations, such as remote monitoring systems, predictive maintenance, and automated ore processing, are poised to increase the efficiency and safety of mining operations in Myanmar.

Moreover, with growing environmental concerns, there is an increasing focus on sustainable mining practices. Crusher with lower energy consumption and reduced environmental impact are becoming more desirable in the global mining market. For Myanmar, this presents an opportunity to modernize its mining operations, attract foreign investment, and improve the overall sustainability of its copper industry.

Conclusion

Copper mining plays a pivotal role in Myanmar’s economy, and crusher equipment is central to the process of extracting and refining copper ores. As the demand for copper continues to rise, efficient, durable, and energy-efficient crusher will remain integral to meeting the needs of the mining sector. By investing in advanced crusher technology and embracing sustainable practices, Myanmar’s copper mining industry has the potential to grow and evolve, securing a competitive edge in the global mineral market.