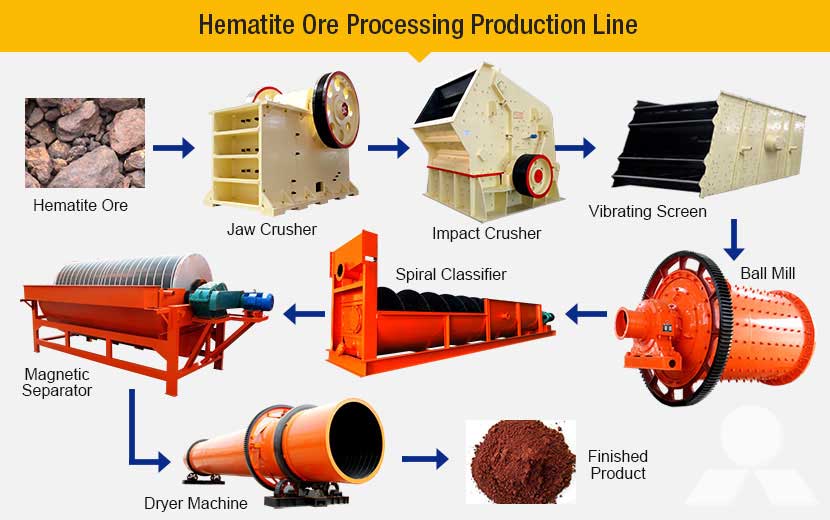

Hematite Crushing and Grinding Process

Hematite is an important mineral resource widely used in fields such as steel, construction, and chemical industry. In the processing of hematite, crushing and grinding are essential steps.

Crushing process of hematite:

Hematite is generally present in the form of large blocks or particles, so it needs to be crushed to reduce particle size and facilitate subsequent grinding and extraction of useful minerals. The crushing process of hematite usually includes the following steps:

- a. Primary crushing: The original hematite is crushed into smaller block materials by equipment such as jaw crushers for primary crushing.

- b. Intermediate crushing: The block materials after primary crushing are further crushed into smaller particle materials by equipment such as cone crushers or impact crushers for intermediate crushing.

- c. Fine crushing: The hematite materials after intermediate crushing usually require further fine crushing. Equipment such as ball mills and fine crushers can be used to crush the particle materials into smaller particles.

- d. Screening: During the crushing process, the materials need to be screened to separate hematite of different particle sizes for further grinding and beneficiation operations.

Grinding process of hematite:

Grinding is the process of refining crushed hematite particles, mainly to increase the exposure and release of useful minerals in the ore for better beneficiation and extraction. The grinding process of hematite usually includes the following steps:

- a. Coarse grinding: The crushed hematite materials are further ground into finer particles by equipment such as ball mills for coarse grinding. The grinding media used in this process is usually steel balls or other hard grinding media.

- b. Intermediate grinding: After coarse grinding, the hematite materials enter the intermediate grinding stage and are further ground into finer particles by equipment such as ball mills to increase the exposure of useful minerals.

- c. Fine grinding: After intermediate grinding, the hematite materials need to be finely ground by equipment such as vertical mills to better release useful minerals.

- d. Classification: During the grinding process, the ore needs to be classified to separate hematite of different particle sizes for subsequent beneficiation operations. Classification is usually performed using screening equipment or hydrocyclones.

Through the crushing and grinding process, the particle size of hematite is gradually refined, and the exposure and release of useful minerals in the ore are increased. This provides better conditions for subsequent beneficiation operations to extract useful minerals from hematite and meet the needs of industrial production.

The crushing and grinding process of hematite is an important part of ore processing, which directly affects the beneficiation effect and product quality. With reasonable process design and equipment selection, production efficiency can be improved, production costs can be reduced, and product quality and market competitiveness can be enhanced to achieve sustainable development.