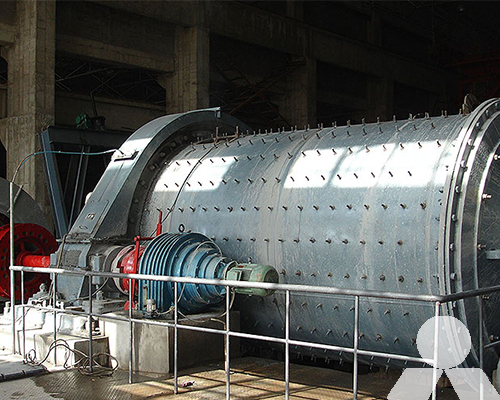

Ball mill used in copper ore beneficiation process in Chile

In the mineral-rich lands of Chile, the extraction and processing of copper have been vital to the country’s economy for centuries. As technology advances, the efficiency and precision of copper ore processing have significantly improved, especially with the application of ball mills in the ore beneficiation process.

The ball mill, a robust and essential piece of machinery in mineral processing, plays a pivotal role in crushing and grinding the copper ore to liberate the valuable minerals from the waste rock. In Chile’s copper mining industry, this process is crucial as it directly impacts the subsequent steps of flotation and smelting.

The primary function of the ball mill in copper ore processing is to reduce the ore to a size small enough for the separation of copper minerals from the surrounding rock. To accomplish this, the ore is fed into the mill, where steel balls grind the ore into finer particles. This grinding action not only breaks down the ore but also aids in the release of the copper minerals, making them accessible for the next phase of the beneficiation process.

Chile’s copper mines, such as Escondida and Chuquicamata, have integrated advanced ball mill technologies into their ore processing circuits. These ball mills are often part of larger processing systems, working in conjunction with flotation cells, thickeners, and other equipment to ensure the efficient recovery of copper.

The efficiency of ball mills has significantly improved over time due to advancements in design, materials, and operating parameters. Modern ball mills can be highly customized, allowing operators to adjust factors such as rotational speed, ball size, and liners to optimize the grinding process for specific ore types and conditions.

Moreover, the use of ball mills in Chile’s copper mining operations has led to better energy efficiency and reduced environmental impact. Newer mills are designed to consume less power per ton of ore processed, contributing to a more sustainable mining industry.

The success of ball mills in Chilean copper ore processing has not only increased the productivity of mining operations but has also improved the quality of the final copper concentrate. This has a direct impact on the market, ensuring a higher-grade product that meets the stringent quality requirements of global consumers.

In conclusion, the integration of ball mills into the copper ore processing workflow in Chile has proven to be a technological milestone, enhancing the efficiency and sustainability of the country’s copper mining industry. As technology continues to evolve, further innovations in ball mill design and operation will likely play a crucial role in shaping the future of copper ore processing.

Chile’s copper mining industry stands as a testament to the successful application of ball mills in the ore beneficiation process, underscoring their indispensable role in the production of this crucial metal.

The adoption of ball mills in Chilean copper mining operations has transformed ore processing, paving the way for increased efficiency and sustainability in the industry. As technology advances, further refinements in ball mill design and utilization will continue to enhance the processing of copper ore, solidifying its pivotal role in the nation’s mining sector.