Copper Ore Crushing Production Line

Our company’s copper ore crushing production line process features high automation, high crushing rate, low operating costs, energy efficiency, environmental friendliness, and fine particle size. Liming Heavy Industry can provide you with a complete set of process flow solutions and technical support tailored to your specific production requirements, ensuring that your needs are met.

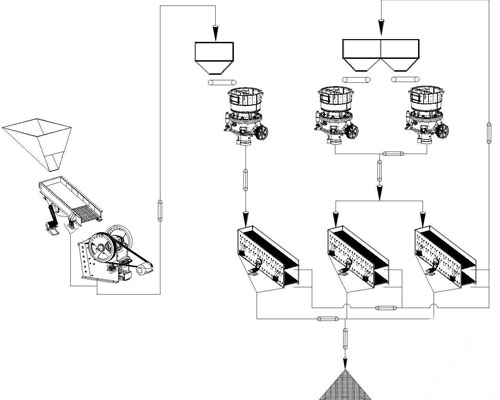

Process Flow:

Copper Ore Crushing:

In the copper ore mining field, large chunks of copper ore are transported from underground mines or surface mines to the copper ore crushing production line by excavators and loaders. They are then uniformly fed into the crushing equipment (such as jaw crushers or mobile jaw crushing stations) through the vibrating feeder. The primary crushing process commences, breaking the large chunks of raw ore into smaller pieces. After coarse crushing, the crushed copper ore undergoes screening and is conveyed by a belt conveyor to a cone crusher for intermediate and fine crushing, further reducing the size of the ore particles.

Copper Ore Grinding:

In the first stage, the raw copper ore obtained from the mining site is processed by various types of copper ore crushing equipment, resulting in ore particles. After being screened by a vibrating screen, these ore particles can be sent to a ball mill for grinding (the ball mill grinds the transported copper ore particles into fine powder for subsequent flotation operations). An auxiliary device called a classifier is used here to grade the copper ore and release the desired copper ore powder.

Copper Ore Flotation:

The ground copper ore powder enters the flotation machine, where various elements present in the ore interact with the chemical solvents added to the flotation machine. The flotation machine separates the copper ore based on differences in characteristics such as gangue minerals, associated metal minerals, and copper’s hydrophilic properties.

Purification and Drying:

The copper ore extracted through the flotation machine is essentially suitable for relevant industrial requirements. After drying in a drying machine, high-value copper concentrate can be obtained.

The commonly used flotation method is employed for copper ore beneficiation. The copper ore dressing equipment includes crushers (coarse crushing and fine crushing), ball mills, classifiers, concentrators, flotation machines, and drying machines. Depending on the composition of the ore, suitable beneficiation processes and equipment are selected accordingly.

The mined ore is first preliminarily crushed by a jaw crusher and, once crushed to a reasonable fineness, is uniformly fed into a ball mill through an elevator and an ore feeder. The ball mill crushes and grinds the ore.

The finely ground ore from the ball mill enters the next process: classification. The spiral classifier washes and classifies the ore mixture based on the different settling rates of solid particles in a liquid due to their different specific gravities. The washed and classified mineral mixture undergoes magnetic separation, separating magnetic materials from the mixture due to the different magnetic properties of various minerals. After preliminary separation by a magnetic separator, the mineral particles are fed into a flotation machine, where different reagents are added based on the characteristics of different minerals, resulting in the separation of the desired mineral from other substances.