Industrial Crusher User Manual

Introduction

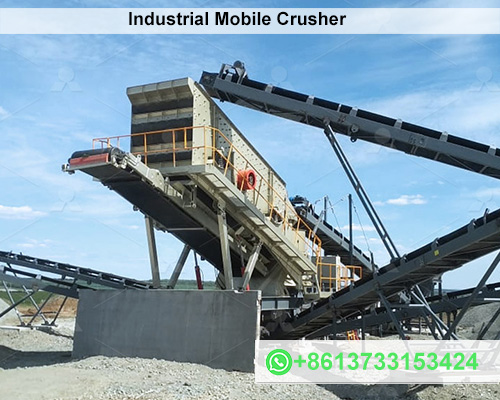

This user manual is designed to provide comprehensive guidance on the operation, maintenance, and safety protocols for industrial crusher. Industrial crusher is essential for reducing the size of materials in various sectors, including mining, construction, and recycling. Proper understanding and adherence to this manual will ensure efficient performance and longevity of the equipment.

Table of Contents

- Product Overview

- Types of Crusher

- Specifications

- Safety Precautions

- General Safety Guidelines

- Personal Protective Equipment (PPE)

- Emergency Procedures

- Installation Guidelines

- Site Preparation

- Mounting and Assembly

- Electrical and Hydraulic Connections

- Operation Instructions

- Starting the Crusher

- Feeding Materials

- Operating Controls

- Maintenance Procedures

- Routine Maintenance

- Troubleshooting

- Parts Replacement

- Storage and Transport

- Proper Storage Techniques

- Transporting the Crusher

- Technical Support and Warranty Information

1. Product Overview

Types of Crusher

Industrial crusher is available in several configurations, including:

- Jaw Crusher: Ideal for primary crushing of hard materials.

- Cone Crusher: Used for secondary and tertiary crushing with a focus on finer material sizes.

- Impact Crusher: Suitable for processing softer materials and providing high reduction ratios.

- Hammer Crusher: Effective for crushing medium to hard materials, often used in mining and cement industries.

Specifications

Refer to the specific model specifications for details on capacity, power requirements, and material compatibility.

2. Safety Precautions

General Safety Guidelines

- Always read the user manual before operating the crusher.

- Ensure all safety guards and covers are in place during operation.

- Never operate the crusher without proper training and supervision.

Personal Protective Equipment (PPE)

- Hard hat

- Safety glasses

- Ear protection

- Steel-toed boots

- Gloves

Emergency Procedures

- Familiarize yourself with the location of emergency shut-off switches.

- In case of an emergency, immediately cease operation and follow evacuation protocols.

3. Installation Guidelines

Site Preparation

- Ensure the installation site is level, stable, and free from debris.

- Provide adequate space for maintenance access and material handling.

Mounting and Assembly

- Follow the manufacturer’s instructions for mounting the crusher securely.

- Use appropriate tools and fasteners to prevent vibrations and movement.

Electrical and Hydraulic Connections

- Ensure all electrical connections comply with local codes.

- Check hydraulic systems for leaks and proper fluid levels before operation.

4. Operation Instructions

Starting the Crusher

- Conduct a pre-start inspection to ensure the crusher is in good condition.

- Turn on the power supply and ensure all safety features are engaged.

- Start the crusher according to the manufacturer’s instructions.

Feeding Materials

- Gradually introduce materials to avoid overloading.

- Do not exceed the specified feed capacity.

Operating Controls

- Familiarize yourself with control panels and indicators.

- Use caution when adjusting settings during operation.

5. Maintenance Procedures

Routine Maintenance

- Regularly inspect wear parts and replace as needed.

- Keep the crusher clean to prevent material buildup.

Troubleshooting

- Refer to the troubleshooting section for common issues and solutions.

- For complex problems, contact technical support.

Parts Replacement

- Use only manufacturer-recommended parts for replacements.

- Follow proper procedures for disassembly and reassembly.

6. Storage and Transport

Proper Storage Techniques

- Store the crusher in a dry, secure location when not in use.

- Protect from extreme weather conditions.

Transporting the Crusher

- Use appropriate lifting equipment and techniques.

- Secure the crusher properly during transport to prevent damage.

7. Technical Support and Warranty Information

For technical support, refer to the contact information provided by the manufacturer. Ensure to keep records of maintenance and repairs for warranty claims.

Conclusion

Following this user manual will ensure safe and efficient operation of your industrial crusher. Regular maintenance and adherence to safety protocols are essential for maximizing performance and prolonging the lifespan of the equipment. Always stay informed of best practices and seek assistance when needed.