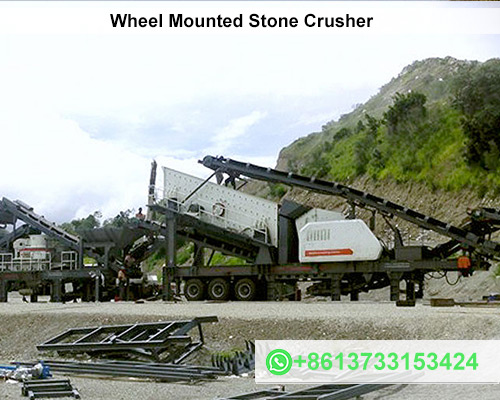

Wheel Mounted Stone Crusher For Sale

In the fast-paced world of mining, construction, and road building, mobility and flexibility are critical factors in choosing the right equipment. The wheel-mounted stone crusher, also known as a mobile stone crusher, offers an ideal solution for projects that require efficient, on-site rock crushing with easy transportation between job sites. Its compact and adaptable design makes it a popular choice for many industries. In this article, we explore the key features, benefits, and applications of wheel-mounted stone crusher, as well as what to look for when purchasing one for sale.

1. What is a Wheel-Mounted Stone Crusher?

A wheel-mounted stone crusher is a portable crushing plant mounted on wheels that can be easily transported from one location to another. It consists of various components, including a crushing unit (jaw, cone, or impact crusher), a vibrating feeder, screening equipment, and conveyors, all integrated into a single mobile platform. The primary advantage of a wheel-mounted unit is its ability to move between job sites quickly and efficiently, reducing the time and cost associated with material transportation.

Wheel-mounted crusher is available in different configurations, allowing users to select the ideal system based on their specific needs. Popular options include:

- Jaw Crusher: Ideal for primary crushing, they handle large stones and break them into smaller pieces.

- Cone Crusher: Used for secondary crushing, these offer high capacity and produce finely crushed materials.

- Impact Crusher: Known for their ability to handle softer materials and deliver high-quality aggregates.

2. Advantages of a Wheel-Mounted Stone Crusher

Wheel-mounted stone crusher offer several advantages that make them an attractive option for industries that require mobile crushing solutions. Below are the key benefits:

a. Mobility and Flexibility

The primary advantage of a wheel-mounted stone crusher is its mobility. Unlike stationary crusher, which are fixed to a specific location, wheel-mounted crusher can be easily moved between different work sites. This is particularly useful for projects in remote or changing locations, such as mining operations, road construction, or infrastructure development. The ability to move the crusher reduces the need for material transportation, saving time and costs.

b. Easy Setup and Operation

Wheel-mounted stone crusher is designed for quick setup and simple operation. The compact design and integrated components allow the crusher to be ready for use within hours of arrival on-site. Most models come with user-friendly control systems, ensuring that operators can start crushing operations with minimal training or technical knowledge.

c. Cost-Effectiveness

The mobility and efficiency of wheel-mounted crusher significantly reduce the costs associated with material handling and transportation. By allowing materials to be crushed on-site, the need for transporting raw stone to a fixed crushing facility is eliminated, lowering fuel costs and labor expenses. Additionally, these crusher have a lower initial investment compared to fully stationary crushing plants.

d. Versatile Applications

Wheel-mounted stone crusher is suitable for a wide range of applications. They can be used for primary and secondary crushing in a variety of industries, including mining, quarrying, road construction, demolition, and recycling. These crusher can handle a variety of materials, including limestone, granite, basalt, and concrete, making them a versatile tool for any project.

e. Environmental Benefits

By reducing the need to transport raw materials to off-site processing plants, wheel-mounted crusher help lower greenhouse gas emissions. On-site crushing also minimizes the carbon footprint of construction or mining projects, contributing to more sustainable practices. Additionally, many models are equipped with dust suppression systems and noise control features, further reducing environmental impact.

3. Applications of Wheel-Mounted Stone Crusher

The flexibility and versatility of wheel-mounted stone crusher make them suitable for a wide range of applications across various industries. Some common applications include:

a. Mining and Quarrying

In the mining and quarrying sectors, wheel-mounted crusher is used to crush and process ore or stone directly at the site, reducing transportation costs and optimizing production efficiency. They can handle large boulders and tough materials, making them suitable for primary crushing of hard rock in mining operations.

b. Construction and Road Building

In road construction, crushed stone and aggregates are essential for the foundation and surface layers of roads. Wheel-mounted stone crusher can be quickly mobilized to construction sites, crushing materials such as gravel, limestone, and asphalt for use in roadbeds and pavement layers. Their mobility is especially valuable for highway projects that require frequent site changes.

c. Recycling and Demolition

Wheel-mounted crusher is also widely used in recycling and demolition projects. They can crush construction and demolition waste, such as concrete and brick, into reusable aggregates. This helps minimize waste sent to landfills and reduces the demand for new raw materials in construction projects.

d. Temporary or Short-Term Projects

For temporary projects or short-term construction needs, wheel-mounted crusher is an ideal solution. Their portability allows for rapid deployment and dismantling, making them suitable for contractors who need flexible crushing solutions on short notice.

4. What to Look for When Buying a Wheel-Mounted Stone Crusher

When searching for a wheel-mounted stone crusher for sale, there are several factors to consider to ensure you select the right machine for your needs:

a. Crusher Type and Capacity

Determine the type of crusher best suited to your project (jaw, cone, or impact) based on the material you need to process. Consider the crusher’s capacity, typically measured in tons per hour (tph), to ensure it can meet the demands of your production.

b. Mobility Features

Check whether the crusher is easy to move, especially if you need to transport it between job sites frequently. Models with advanced mobility features, such as hydraulic or pneumatic systems for easy maneuvering, may offer additional advantages.

c. Durability and Build Quality

Choose a crusher built with high-quality materials that can withstand harsh conditions, especially if the machine will be used in challenging environments like mining or quarrying. A robust frame and reinforced components ensure longer service life and better performance.

d. Fuel Efficiency

Look for fuel-efficient models that can operate cost-effectively over long periods. With fuel prices fluctuating, an energy-efficient machine can provide significant savings over time, especially for projects with extended operating hours.

e. Maintenance and Support

Ensure that the wheel-mounted crusher you purchase is easy to maintain, with accessible parts and support from the manufacturer. Regular maintenance is critical to maximizing the machine’s operational efficiency and lifespan.

5. Conclusion

Wheel-mounted stone crusher offer a practical and versatile solution for a variety of industries, from mining and quarrying to construction and recycling. Their mobility, cost-effectiveness, and ease of operation make them a valuable tool for companies looking to improve productivity while reducing operational costs. When purchasing a wheel-mounted stone crusher for sale, it’s essential to evaluate factors such as crusher type, capacity, mobility, and durability to ensure the machine meets your specific needs. With the right equipment, businesses can streamline their crushing operations, improve efficiency, and achieve significant cost savings.