Cost of new quartz crushing machine

Quartz is a common building material, widely used in construction, decoration, and other fields due to its hard texture, wear resistance, and high temperature resistance. However, the texture of quartz also makes it difficult to handle during the processing, requiring specialized crushing equipment to break it into appropriate particle sizes. Therefore, the complete set of quartz crushing production line equipment has become one of the important equipment in the quartz processing industry.

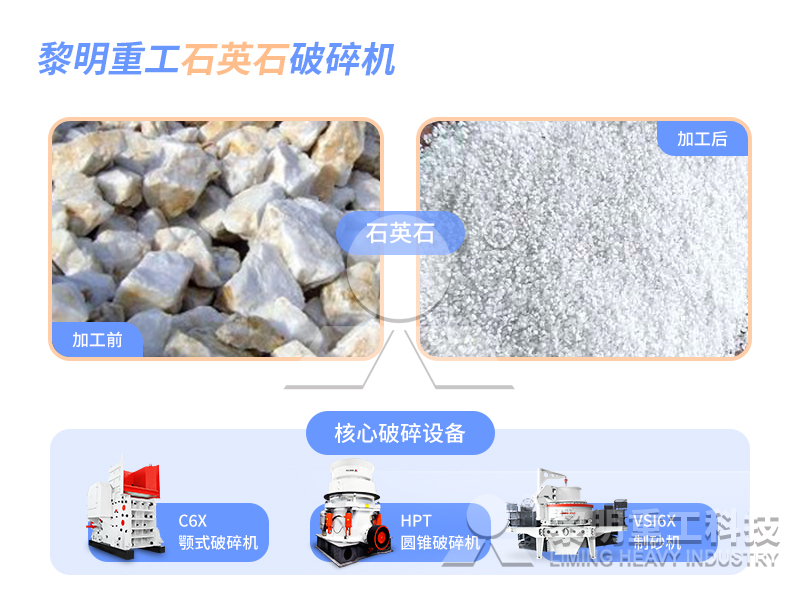

The complete production line equipment for quartz crushing usually includes a combination of multiple equipment such as vibration feeder, jaw crusher, impact crusher, cone crusher, screening machine, etc. The vibrating feeder is mainly responsible for feeding the raw material quartz into the crushing equipment for processing; The jaw crusher is one of the more commonly used crushing equipment, which can quickly crush quartz into small particles and adjust the size of the discharge port; The impact crusher has the characteristics of high efficiency and energy conservation. It can not only effectively crush quartz, but also re crush it to improve processing efficiency; The cone crusher is suitable for medium hardness quartz, with a compact structure and simple operation, which can crush quartz into smaller particles. Later, the screening machine can screen the crushed quartz stone to obtain quartz stones of different particle sizes, and can crush them again as needed.

The cost of quartz crusher varies due to various factors such as model, specifications, production quality, brand, region, and market supply and demand relationship. Generally speaking, larger scale and high-quality quartz stone crushers are relatively expensive because they use more advanced technology and more durable materials.

In addition, when purchasing a quartz crusher, in addition to the cost of the equipment itself, it is also necessary to consider transportation, installation, debugging, and later maintenance costs. Therefore, when determining the cost of quartz crusher, it is necessary to comprehensively consider these factors.

Please note that the specific cost may vary depending on the specific situation. It is recommended to directly contact the manufacturer or supplier of the quartz crusher to obtain the most accurate price information. At the same time, when purchasing, factors such as equipment performance, efficiency, stability, and after-sales service should also be considered to ensure the purchase of products with high cost-effectiveness.