Sand and gravel aggregate line crushing equipment and combination

The extensive use of artificial sand and gravel aggregates has led to an increase in the production of artificial sand and gravel aggregate production lines. Here, we will discuss the crushing equipment and combination forms of sand and gravel aggregate production lines.

1. Common crushing equipment for sand and gravel aggregate production lines and their characteristics

Domestic aggregate production crushing equipment generally adopts coarse crushing and fine crushing. Coarse crushing usually uses gyratory crushers, hammer crushers, impact crushers, and jaw crushers; fine crushing usually uses impact crushers and cone crushers.

(1) Hammer crusher

The advantage of the hammer crusher is that it only requires one stage of crushing and has a simple process. However, the disadvantage is that after the material is crushed by the hammer, the yield of large pieces of finished product is low, and it is prone to over-crushing, resulting in more powdery materials. The finished material may have microcracks, which can reduce the compressive strength and affect the quality of the aggregate, thus affecting sales.

(2) Jaw crusher

The advantage of the jaw crusher is that it has a simple structure, light weight, low price, easy installation and maintenance, requires a small plant height, and has a reliable operation. The discharge port is easy to adjust, especially for ores with high moisture and large viscosity, which are not easy to block. The disadvantage is that the lining plate is easy to wear, and the crushing product has uneven particle size, requiring the configuration of feeding equipment.

(3) Impact crusher

The impact crusher is a new type of high-efficiency crushing equipment. Its characteristics are small size, simple structure, high crushing ratio, low energy consumption, large production capacity, uniform product size, and selective crushing of minerals, which has great development potential. The biggest disadvantage of the impact crusher is that the plate hammer and counterattack plate are particularly prone to wear, especially when crushing hard ore, the wear is more severe, and frequent replacement is required.

(4) Gyratory crusher

The advantage of the gyratory crusher is that it has a large processing capacity, good particle shape of the product, low unit energy consumption, does not require the configuration of feeding equipment, and the lining plate wear in the crushing chamber is uniform. The disadvantage is that the equipment has a complex structure, high price, heavy weight, requires a strong foundation, high body height, requires a high plant height, and has high civil construction investment costs, making maintenance difficult.

(5) Cone crusher

The cone crusher is mainly suitable for crushing rocks with a higher hardness and abrasiveness index. Its advantages are high crushing force and stable operation. The disadvantage is that the equipment investment is large, the crushing ratio is small, the product particle shape is poor, and it is often needle-like.

2.Factors and Characteristics of Crushing Combination Form

The factors affecting the crushing equipment and combination form of sand and gravel aggregate production lines mainly include production scale, financial status, maintenance and repair volume, product performance and proportion, etc. Among the sand and gravel aggregate production lines that have been put into operation in China, those with a production scale of 200 tph, 300 tph, 400 tph, and 500 tph are more common. Production lines with a scale of 1,000 tph and above mainly use gyratory crushers for production, which are mainly used by some large enterprises due to the high equipment investment and infrastructure installation costs.

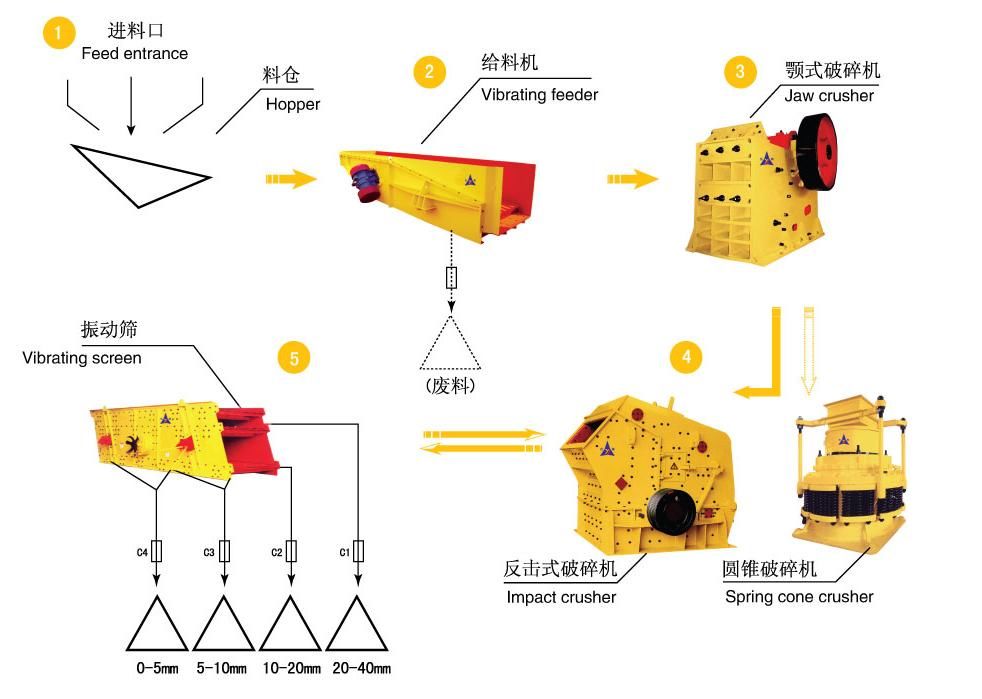

The more common crushing combination forms include jaw crusher + impact crusher, impact crusher + impact crusher, jaw crusher + cone crusher, etc.

The main characteristics of the jaw crusher + impact crusher combination are good product granularity, low total investment, low energy consumption, less powder, moderate maintenance and operation costs, and moderate impact on the environment such as noise and dust.

The main characteristics of the impact crusher + impact crusher combination are good product granularity, high energy consumption, high maintenance and operation costs, large noise and dust, and a relatively large proportion of 0-5 mm finished products, which is mainly suitable for enterprises with a large demand for machine-made sand.

The main characteristics of the jaw crusher + cone crusher combination are suitable for crushing rocks with high hardness and abrasion resistance index, a small proportion of powdery materials, low maintenance and operation costs, less noise and dust than the previous two, a large initial investment, high energy consumption, and poor product granularity (mostly needle-shaped).

In the sand and gravel aggregate production line, the choice of crushing equipment and combination form is often the first consideration. With the use of new technologies and materials, crushing equipment and combination forms will also present new characteristics, such as the technical transformation of fine crushing cone crushers, which has greatly reduced the production of needle-shaped products. By analyzing and choosing reasonably among various influencing factors and the company’s own conditions, and paying attention to the development of new technologies in crushing equipment, the optimal solution can be obtained.